Leland NC – In recent years, the construction industry has been searching for more sustainable and environmentally friendly materials to build structures that are durable, strong, and visually appealing. As the industry seeks to reduce its environmental impact, a new material has been emerging as a viable alternative to traditional concrete: Stainless Steel. Stainless steel offers a range of appealing answers, from sustainability to strength and durability, making it an ideal choice for a variety of projects – Pool Construction for one – BRADFORD PRODUCTS (click link)

Better for the Environment: Almost all in-ground pool construction uses concrete as the foundation, involving significant energy consumption and resulting in additional carbon dioxide emissions that contribute to climate change. According to the Association of Pool and Spa Professionals (APSP), there are an estimated 10.4 million residential and 309,000 public swimming pools in the United States as of 2020 (and growing) – making this a considerably serious issue. On the other hand, stainless steel, unlike concrete, is 100% recyclable and can be reused without any loss of quality.

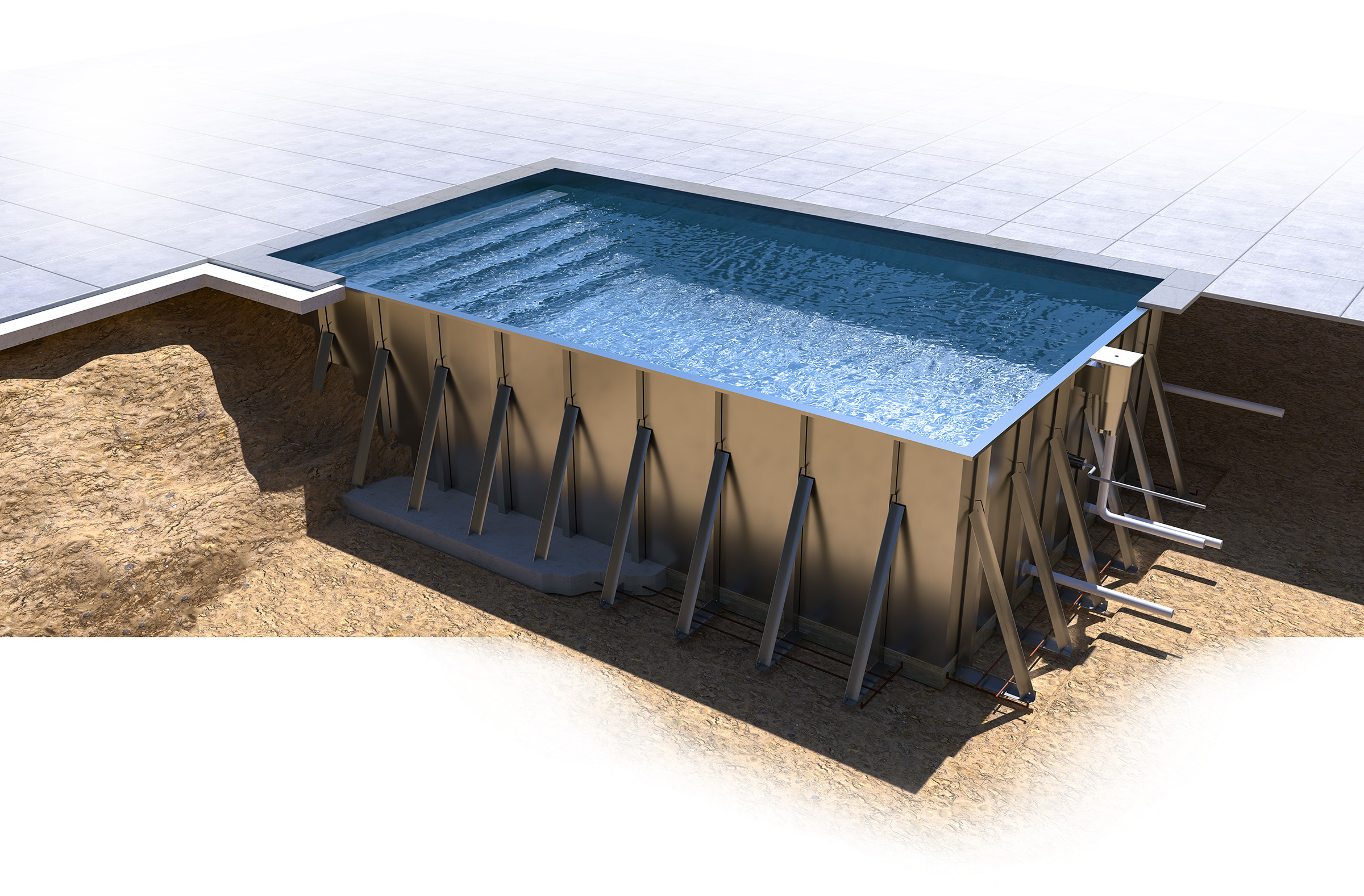

The MPool being installed for the home

Versatility: Stainless steel is a highly versatile material that can be easily shaped and formed into a variety of designs. This allows architects, designers, and builders to create visually stunning pools and spas that are both functional and aesthetically pleasing. Since Stainless steel is 1/3 to 1/4 of the weight of concrete or shotcrete, Bradford vessels can be installed in a fraction of the time. It also makes this material perfect for elevated/rooftop projects.

Strength: Stainless steel is virtually indestructible. The structural integrity of Bradford-engineered pools and spa designs allows Bradford to offer an unprecedented 25-year warranty on the stainless steel shell. The integral stainless steel frame supports the entire vessel without the need for any backfill or extra bracing. Bradford pools and spas are designed to be fully self-supporting and provide excellent strength-to-weight ratios.

Lighter stainless steel is perfect for elevated jobs

Durability: Another advantage of stainless steel pools and spas is durability. They can withstand harsh environments and extreme weather conditions. Stainless steel is highly resistant to corrosion and rust, which means it does not require additional coatings or treatments to protect it from the environment. It has a longer lifespan than concrete, reducing the need for replacement or repairs and, in turn, reducing waste and the need for additional resources. Unlike concrete, which requires frequent cleaning and repair, stainless steel is low maintenance and resistant to staining, corrosion, and UV damage.

Hygiene: Stainless steel is a non-porous material that is easy to clean and disinfect, with a mild detergent. It also provides an effective barrier against the buildup of bacteria, black spot, mildew, and other germs which can stain surfaces like concrete, acrylic, fiberglass, and vinyl liners. This unique property is exactly why stainless steel is utilized in everything from commercial kitchens to specialized sterile hospital equipment.

For over 40 years and over 10,000 installations completed, Bradford’s products are featured in facilities and homes across the globe. We work with aquatic designers, architects, owners and developers, custom home builders, general contractors, pool builders, and designers to create sensational, long-lasting stainless steel aquatic vessels. As the construction industry continues to prioritize sustainability and reduce its environmental impact, Bradford’s stainless steel is likely to play an increasingly important role in the years to come.